All fire safely systems must be in good working order.

Fire dampers are crucial fire protection assets designed to save lives, and a faulty ill-maintained fire damper will not prevent the spread of fire.

Under the Regulatory Reform (fire safety) Order 2005 a responsibility is placed on the building owner and/or employer to professionally maintain their fire safety systems.

At Essential our team of operatives are trained to carry out fire and smoke damper testing to comply with BS 9999:2017 Code of Practice for Fire Safety in the Design, Management & Use of Buildings. BS 9999:2017 are the standards used as guidance to ensure compliance with the Regulatory Reform (Fire Safety) Order 2005.

Fire Damper Survey

The first step towards fire damper compliance is a survey to seek and identify what you have within your premises. Surveys can be carried out using ventilation schematics and/or building plans or carrying out physical inspection of your premises (mostly both).

The purpose of a survey is to generate an asset register or an estimation of the number of fire dampers at your premises, whilst also assessing the general accessibility of the dampers.

Once the survey is carried out the information gathered will be used to generate a quotation for a full inspection and testing service.

Ventilation schematics?

Most modern commercial and industrial premises come with detailed ventilation layout schematics which illustrates all the ductwork assets such as fire and smoke dampers, and volume control dampers.

Essential operatives are very experienced in navigating around a premise using the ventilation schematics or building plans and can either work with printed copies (originals will be returned) or digital copies.

Do not have Ventilation schematics or out-of-date?

No problem… Ventilation schematics are a very useful tool to have available when carrying out a survey, however many older buildings no longer have copies of their schematics or have undergone refurbishment works or alterations which have altered the ventilation and compartment layout.

Essential operatives are very experienced in the seek and location of dampers. Either by tracking the ductwork routes from AHU source or locating fire compartments which have ductwork penetrations, our operatives can generate a portfolio of your damper assets.

How intrusive is the survey?

Assessing the general accessibility of the fire dampers throughout a premise is one of the main objectives in a survey. Fire dampers are normally tucked away in ceiling and riser voids requiring ladders and/or removal of obstructions, however our operatives will never cut into duct work or building fabric to check for fire dampers. Should a fire damper be visible or illustrated on the ventilation schematic but not accessible, they will be recording on the asset register and recommended actions detailed within the service report.

What happens after the survey is complete?

Once the survey is carried out the information gathered will be used to generate a quotation for a full inspection and testing service.

Fire Damper Inspection and Testing

BS 9999:2017 states:

Arrangements should be made for all fire dampers to be tested by a competent person on completion of the installation and at least annually, and to be repaired or replaced immediately if found to be faulty ”

To reach fire damper compliance each damper must be inspected, and a drop test carried out. The first step to fire damper test procedure is a visual inspection. The visual inspection is carried out on the damper to ensure the following:

Many faults or defects can be identified during the initial inspection. Should there be an accessibility issue, obstruction, or damage to the damper, these will be noted as required remedial actions. Once all visual inspections are complete and satisfactory, a drop test can be carried out.

What is a fire damper drop test?

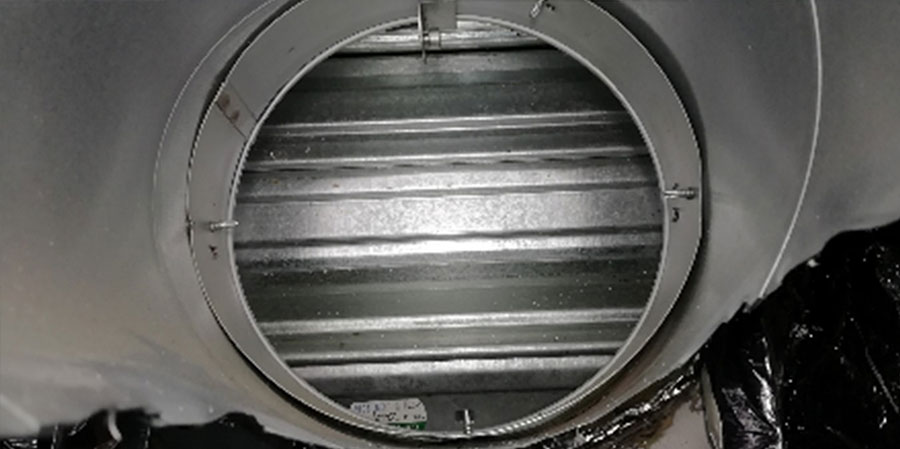

Fire dampers form part of a building ventilation system and are installed where air handling ducts pass through fire-separating elements such as compartment walls or enclosures protecting escape routes.

Typically, a fire damper is a metal curtain within a duct held up by a thermal element (referred to as a fusible link) and released in the event of a rise in temperature. The thermal element will melt at a set temperature releasing a spring-operated metal curtain, which is pulled down to fill the opening the duct passes through, preventing the passage of fire.

During a fire damper drop test the operative will:

Why do dampers need to be cleaned?

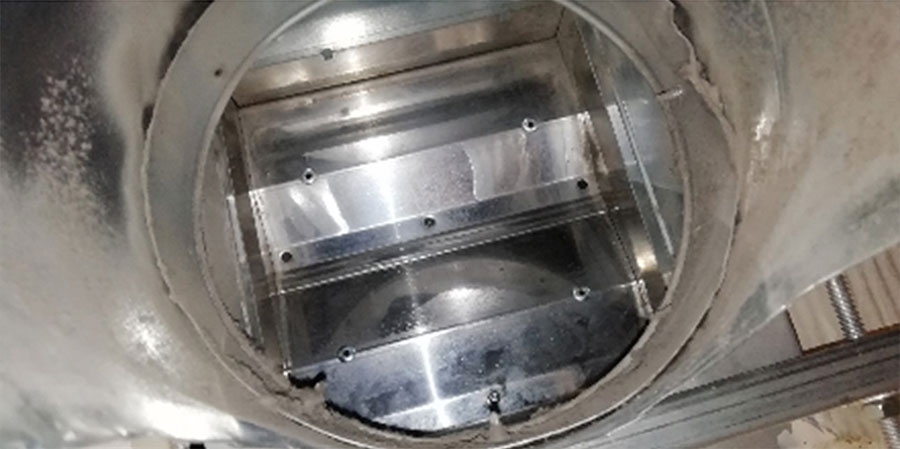

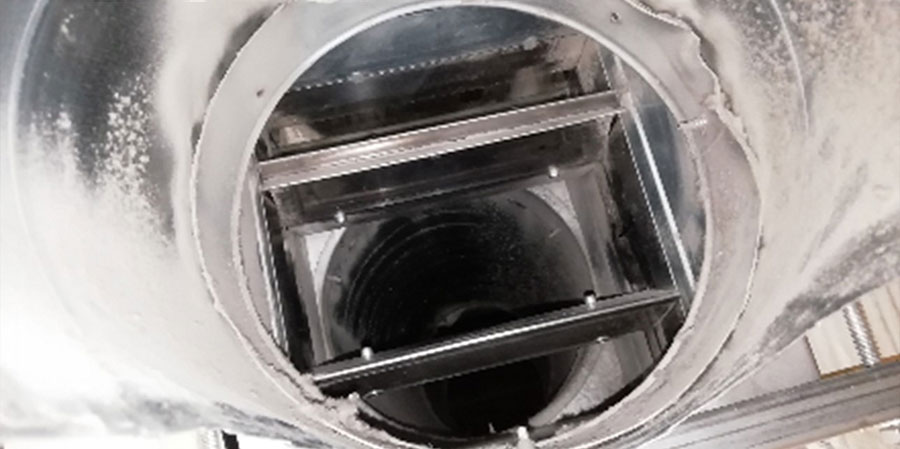

Fire and smoke dampers are passive fire protection assets subjected to constant air flow through the building ventilation systems. As a result, dampers can accumulate a buildup of dust and debris negatively impacting the performance of the damper.

How often should you conduct fire damper testing?

In most cases routine inspection, testing and maintenance is required every 12 months. However, in dust linden environments more frequent testing is required. Dampers in hospitals or high-risk environments will also require more frequent testing.

Evidence of fire damper testing?

Completion of the fire damper inspection and testing routine will not satisfy compliance. You need to be able demonstrate and provide appropriate evidence that fire dampers (as part of your safety systems) are being maintained.

Essential provides one of the most comprehensive reports available on the market. Including full photographic evidence of testing and observations.

Fire Damper Remedials

BS 9999:2017 states:

Arrangements should be made for all fire dampers to be tested by a competent person on completion of the installation and at least annually, and to be repaired or replaced immediately if found to be faulty”

Upon completion of your annual inspection and testing your report may highlight some faults and defects with dampers which require remedial action.

If any damper is found to be faulty, our operatives will discuss remedial options with you, and will issue a quotation for remedial works along with the service report detailing the defects.

Essential team of operatives have experience in delivery remedial solutions for all common faults: